Enquiry telephone

400-680-8962Qingzhou Jinhao new material Co., LTD

Add:No.19, Jingting Street, Caterpillar Industrial Park, Qingzhou City, Shandong Province,China

contact us 2023-2-24

2023-2-24

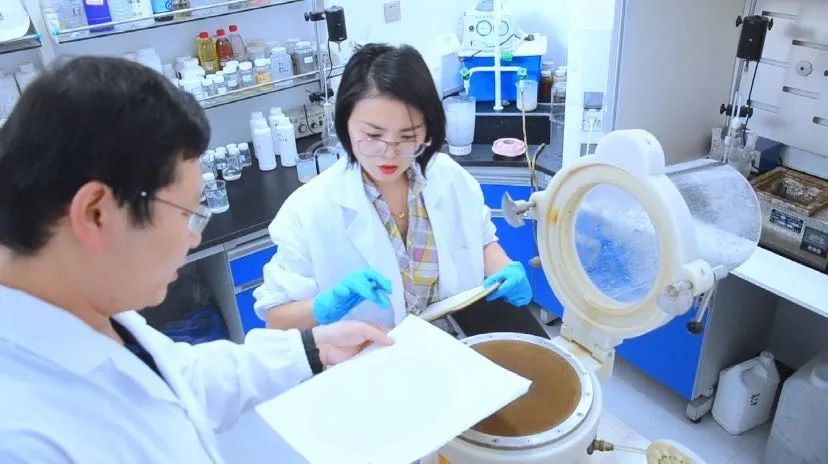

First, product introduction:

1216 series dry strength agent is a new product developed by our company using advanced research and development testing instruments and large-scale production equipment. This product is a bi-ionic type, which can be directly adsorbed to the pulp fiber and form ionic bond through the combination of ions to improve the bond strength between fibers. At the same time, it can effectively improve the physical indexes of paper such as breaking resistance, folding resistance, tension, peeling strength, etc. The products are widely used in the production of paper such as box board paper, yarn tube paper, cardboard paper, mold, special paper, cultural paper, household paper, etc.

Two, the main technical indicators:

Appearance: Colorless translucent liquid

Solid content: 15%±1%, 20%±1

Viscosity: 3000-10000mpa.s (25℃)

Ionic type: bisexual ion

PH value: 3-6

Water solubility: easy to dissolve in cold water

Third, performance characteristics:

1. It can significantly improve the breaking resistance, folding resistance, ring compression strength, tensile strength, stiffness and other physical indexes of special paper and cultural paper.

2. Improve the retention rate of fine fiber and filler, improve the water filtration performance; Improve production efficiency and reduce costs.

Iv. Usage and Precautions:

1, recommended dosage: 8-20kg/t paper; It can also be increased or decreased according to the paper needs.

2, need to be diluted with water, dilution times are generally 10-40 times. Add water first and slowly add a small amount of this product in the stirring state. Continuous addition requires the configuration of a dedicated dilution device and connection of the join point.

3. It is recommended to choose the inlet pipe of the slurry pump before copying to continuously dilute the addition.

V. Packaging and storage:

50kg, 1000kg plastic drum packing. Store in a cool and ventilated place. Storage period: 6 months